BoVi, our AI Visual Inspector is used by Manufacturing units looking to reduce customer product rejection due to quality gaps caused by inefficient human checks.

BoVi automates product quality inspection and enforces standardization of raw material quality by detecting and eliminating unwanted foreign particles that may otherwise bypass traditional checks in manual and semi-automated systems. It addresses the challenge of maintaining standardized product quality in manufacturing lines by automating the quality inspection process. By automating the quality inspection process, it eliminates the need for human intervention and ensures 100% product inspection at a significantly faster pace, resulting in a 20% improvement in cost efficiencies.

The BoVi AI Visual Inspection platform is simple to deploy and provides production data and real-time Overall Equipment Effectiveness (OEE) reports to the Quality Control (QC) team. It employs cloud and edge-based systems with real-time backend support for AI models that detect any quality lapses in real-time. This solution reduces product rejection rates by detecting defects that may bypass traditional checks, ultimately improving product quality and customer satisfaction.

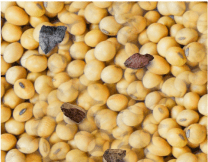

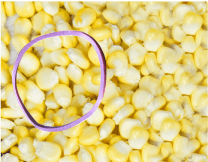

AI Sorter is a game-changer in agricultural sorting. This advanced AI technology is revolutionizing the process by automating the detection and removal of foreign objects with exceptional accuracy. By leveraging AI, we are simplifying and speeding up the sorting process, reducing human effort and time significantly.

AI Sorter has the ability to continuously learn and adapt, ensuring efficient and consistent removal of unwanted materials. With AI Sorter companies can swap manual sorting with a new era of efficiency and productivity in agriculture.

It is designed to identify Category Type#1 (inorganic materials like plastics), Category Type#2 (organic materials like feathers, insects) and remove them from agri-products with very high accuracy and minimal wastage.

Feathers

Strings

Organic Materials

Stones

Metals

Rubber/Papers