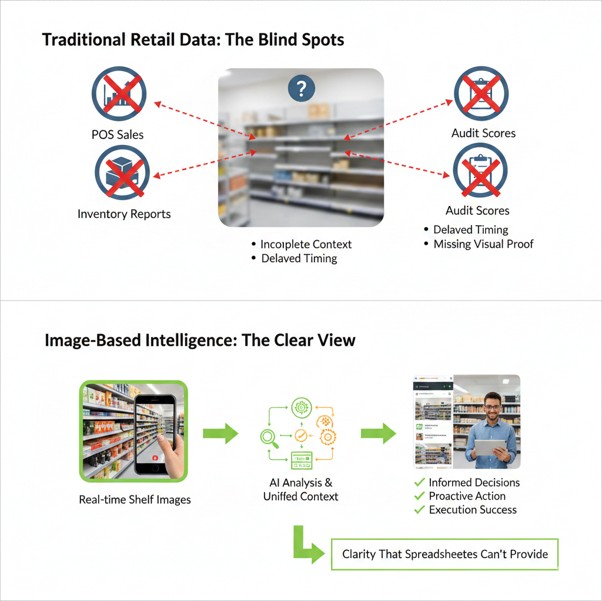

Why Retail Data Without Images Is Incomplete and How Poor Visibility Drives Up to 20% Sales Loss

You review dashboards each week. Sell-through looks stable. Inventory reports show stock in the system. Audit scores sit within the target.

Then sales dip in specific stores. Promotions underperform. Customers shift to competitors.

The shelf already showed the problem. Your reports did not.

Retail shelves change by the hour. Products move. Competitors adjust placement. Store staff reorganize displays. Promotions lose visibility. Internal reports arrive days or weeks later.

This time gap creates delayed shelf intelligence. Leaders act on past conditions. Strategy drifts from execution. Revenue erodes quietly.

Numbers tell you what sold.

Images show what shoppers saw.

1. How Delayed Shelf Data Quietly Erodes Revenue

Revenue loss from delayed shelf insight rarely appears as a single failure. It builds in small daily gaps.

Consider visibility.

IHL Group data shows up to 8% of potential sales vanish because products are not visible enough on shelves. Eye-level placement increases sales by 23% compared to bottom shelf placement. Poor visibility also raises markdown rates by 15% above benchmarks for retailers without real-time data.

Now connect visibility to shopper behavior.

When shoppers cannot find products:

- 41% abandon the purchase due to poor placement

- 34% forego the purchase when facing empty or hidden shelves

- 32% switch brands

- 64% choose a competitor when preferred items are not visible

- More than 70% switch brands in phantom inventory situations, where stock exists but is not displayed

- One in three shoppers switches stores entirely

Source: A Closer Look (ACL)

Poor visibility creates sales loss even when stock exists. Internal systems show availability. The shelf shows an absence.

This gap traps revenue in three ways:

- Missed purchases

- Brand switching

- Store switching

Over time, repeated small losses create a noticeable impact in high velocity categories where visibility drives impulse buying.

2. Operational Blind Spots Created by Late Visibility

Delayed shelf intelligence fractures alignment across teams.

Planners review POS trends. Regional managers review audit summaries. Store teams react to daily pressures. Each group sees partial signals.

Without visual proof:

- Forecasts rely on incomplete assumptions

- Field visits target the wrong stores

- Promotions appear compliant on paper but fail in-store

- Inventory rebalancing reacts too late

Trust in data weakens. Leadership questions dashboards. Field teams question targets. Ownership blurs.

Late visibility also distorts inventory signals. You may see stock in the warehouse. You may see inventory in the system. Yet products remain in the backroom or are misplaced on the shelf.

This creates phantom availability.

A simple table shows the difference:

| Data Type | What It Shows (The Signal) | What It Misses (The Blind Spot) |

|---|---|---|

| POS Sales | Units sold and transaction velocity. | Shelf position, brand visibility, and promotional compliance. |

| Inventory Reports | Stock levels currently recorded in the system. | Shelf gaps, misplaced items, or stock stuck in the backroom. |

| Audit Scores | A snapshot of compliance at a specific moment. | Daily execution fluctuations and real-time shelf health. |

| Shelf Images | Real-time placement, share of shelf, and visual proof. | No gaps; provides the execution context missing from raw data. |

Numbers without images lack execution proof.

3. Missed Action Windows and Their Compounding Impact

Retail runs on timing.

Replenishment windows close quickly. Promotional periods last days. Seasonal demand spikes without warning.

When insight arrives late:

- Stockouts persist for hours or days

- Promotions lose prime launch momentum

- Competitors capture impulse demand

- Assortment adjustments lag behind demand shifts

Small delays scale across hundreds or thousands of stores.

A two-day stock gap in 500 stores creates lost volume at scale. A misaligned promotion across regions weakens national campaigns. A misplaced display reduces conversion during peak footfall.

Repeated missed windows push teams into reactive mode. You fight yesterday’s problems. You plan cautiously. Agility slows.

Customer trust declines. Shoppers who switch brands rarely return quickly. In dense urban markets with high store density, switching happens instantly.

4. Decision Latency and Competitive Exposure

Decision latency measures the time between observing a condition and acting on it.

Delayed shelf intelligence increases decision latency at every level.

- Store teams wait for direction

- Regional managers wait for validation

- Headquarters waits for consolidated reports

Each delay widens the gap between shelf reality and executive intent.

Competitive exposure grows during this gap.

If a competitor secures eye-level placement for three days before detection, you lose visibility and impulse conversion. If your promotion signage is missing during a launch weekend, competitors capture attention.

Over time, repeated delays create caution. Leaders hesitate. Field teams rely on guesswork. Execution quality varies widely.

5. Why Real-Time Shelf Intelligence Changes Retail Outcomes

Real-time shelf intelligence shortens the distance between observation and action.

When teams see live shelf conditions:

- Replenishment aligns with actual gaps

- Promotions are corrected within hours

- Planogram deviations trigger fast fixes

- Field visits prioritize high-risk stores

Continuous visibility supports faster learning cycles. Teams test placement. Review image-backed results. Adjust quickly.

You shift from periodic correction to continuous optimization.

The shelf becomes a live performance signal rather than a post-event report.

6. From Data Collection to Execution Clarity

Image recognition complements traditional data. It adds context to POS and inventory signals.

Here is how the loop works:

- Capture shelf images in the store

- Analyze visibility, compliance, and gaps

- Deliver insights within minutes

- Act immediately at the store level

- Monitor improvement

This cycle reduces decision latency. It replaces subjective audits with objective evidence. It standardizes measurement across regions.

Image-based intelligence answers practical questions:

- Is your SKU at eye level?

- Is promotional signage installed correctly?

- Are competitors occupying premium space?

- Are stock gaps visible to shoppers?

Numbers explain what happened.

Images explain why.

7. The Future of Retail Execution Is Visual and Predictive

AI-driven shelf monitoring improves speed and accuracy.

Deep learning models analyze thousands of shelf images with more than 95% predictive accuracy. Processing time falls below two minutes.

Real-time dashboards present:

- Visibility status

- Planogram compliance

- SKU stock gaps

- Promotional adherence

Predictive models forecast KPI risks linked to:

- SKU shortfalls

- Compliance deviations

- Visibility norms

This approach scales across categories. It works in grocery, personal care, electronics, and general merchandise. Category-agnostic intelligence enables exponential expansion across store networks.

Reduced dependence on manual audits lowers error rates. Continuous image capture replaces static snapshots.

8. Constems AI: Reducing Decision Latency at Scale

Retail success depends on what shoppers see. Shelf visibility drives revenue and customer satisfaction.

Constems AI delivers AI-based Retail Vision Intelligence in real-time. The platform reduces decision latency and improves operational clarity across large retail networks.

CAInatics, the proprietary Image Recognition and Analytics platform, digitizes and optimizes retail space execution.

Brands achieve the ‘picture of success’ through:

- Real-time image capture through mobile devices

- Deep learning analysis with 95% plus accuracy

- Actionable insights in under two minutes

- Live dashboards for management visibility

- Forecasting of KPI risks linked to SKU gaps and compliance

9. How Does it Work?

Image Capture: Field auditors and sales representatives use a guided mobile app to click shelf and display images using existing devices.

Recognition: Images sync to the CAInatics backend AI engine. Deep learning models analyze compliance, stock gaps, and visibility elements within 180 seconds.

Analytics: Hierarchical dashboards display visibility status, compliance metrics, and SKU gaps in real time. API and SDK options integrate with existing systems.

Management teams access live reports for immediate intervention. Field teams receive clear next steps at the store level.

CAInatics operates across product categories and supports large-scale deployments. It ranks among the fastest and most advanced image recognition tools in retail.

By converting shelf images into structured intelligence, Constems AI improves revenue capture, strengthens customer satisfaction, and aligns strategy with execution.

Book a demo today to see how real-time retail vision intelligence drives measurable performance gains.

Book a DemoFAQs

High store density increases switching behavior. When products lack visibility, shoppers shift instantly to nearby competitors.

Live shelf images reveal actual stock gaps, reducing phantom inventory and aligning replenishment with true demand.

Image-based monitoring confirms promotional signage and price visibility, protecting campaign impact and reducing lost conversions.

Yes. Planners, supply chain teams, regional managers, and leadership rely on accurate shelf signals to align forecasts and strategy.

Constems AI uses CAInatics to capture shelf images, analyze them with deep learning in under two minutes, and deliver real-time dashboards with predictive KPI insights for fast action.